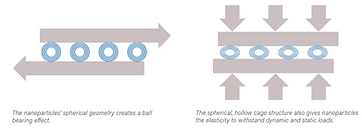

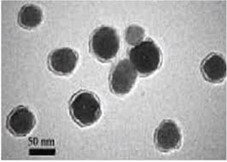

TUNGSTEN DISULPHIDE

SPHERICAL

NANO PARTICLES

These nanoparticles offer excellent friction reduction & shock absorbing characteristics they can with regular use help to refurbish metal surfaces. We use tungsten in two of our products IWRC & CLP-X

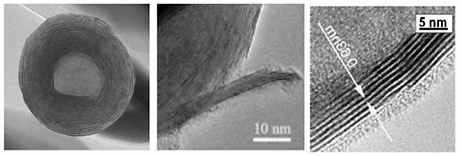

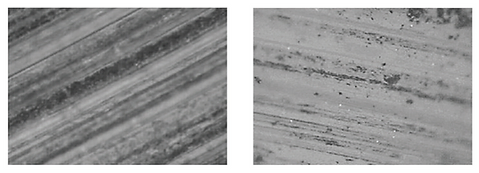

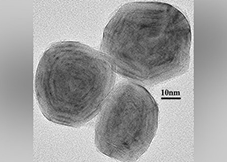

CLEAR CARBON

NANO PARTICLES

Offer excellent tribal film strength with a very low co-efficient of friction with excellent heat wicking properties

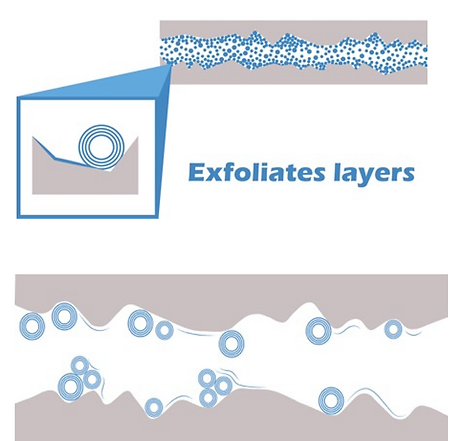

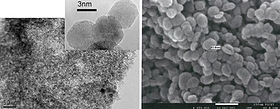

GRAPHENE

NANO PARTICLES

Is the new wonder nanomaterial made of carbon consisting of a multi layer of atoms arranged in a two-dimensional honeycomb lattice nanostructure.

It has the best electrical conductivity as well of heat transferring properties of any element currently know to science. We use Graphene in our Nanocool product